A Medical Devices Rapid Prototyping Facility funded by BIRAC as a part of National Biopharma Mission Supported by DECPL and IESA

Marathwada MedTech Lab is established with funding and mentoring from Bio-Technology Industry Research Assistance Council (BIRAC) established under National Bio-pharma Mission. It offers and immense advantage of connection to the researchers and mentors at national level.

MIT Offers RPT facility along with material testing, staff training and consulting services in certain domains, funding and incubation assistance, mentoring and industry connect, all under one roof.

MIT has collaborated with group of industries represented by NETRA Accelerator Foundation and Deogiri Electronic Cluster Pvt. Ltd. to establish rapid prototyping facility at Aurangabad. Such a facility complements the initiatives of the local industry association CMIA and brown field manufacturing cluster.

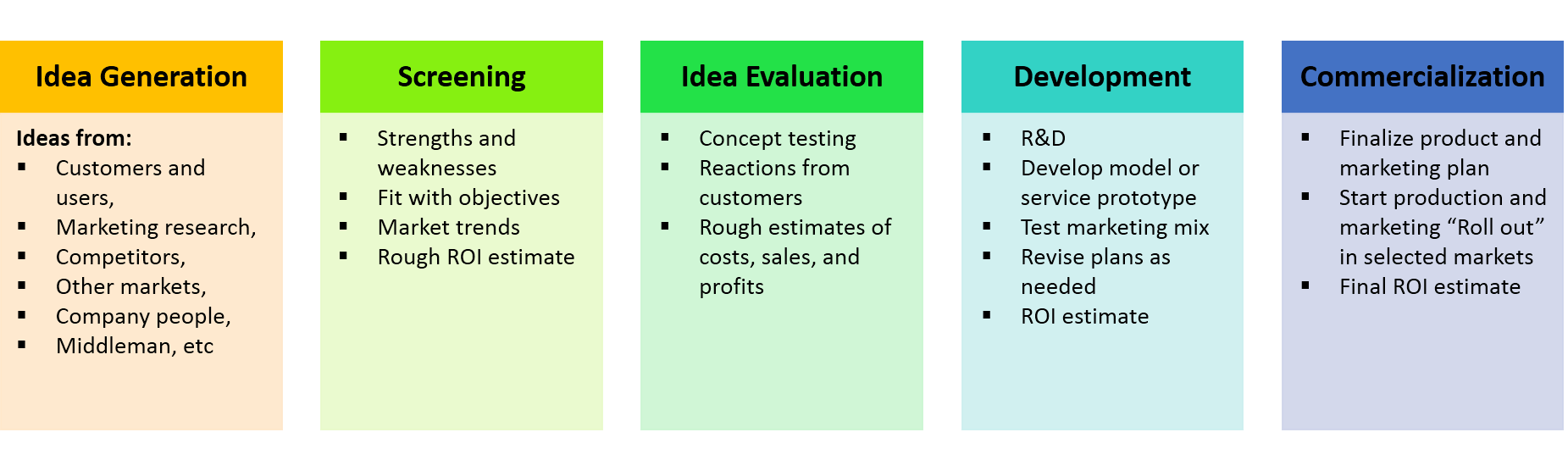

Product development challenges are myriad, and shortening time to market is the number one strategic goal of innovator/entrepreneur and organizations. One such challenge is post proof concept stage (POC) work. Brining out a fully functional product for validation, risk mitigation, and addressing scale-up concerns requires a fully functioning ecosystem of infrastructure, workforce, parts vendors, and mentors.

A Rapid Prototyping Centre (RPT) is a go-to place for all such requirements to help convert a POC into a functional product. An RPT may need to integrate few critical facilities under a single roof to save time, cost, and effort to ensure the required flexibility to do, undo and redo WHATEVER required to achieve goals.

Quicker To Innovate Faster To Validate

Conceptualizing many design options needs a faster validation mechanism, so that after feedback is received, designs can be refined and this iterative process continues till the design meets the required performance criteria.

Reduce Non-productive Investment

Since 3D printing does not require dies, jigs, fixtures, the entire development cycle can be accomplished with reduced expenditure in a shorter period. Before committing considerable resources in full-scale manufacturing, an entrepreneur can cut losses by withdrawing potentially failure products.

Reduce Time-to-market

Design and performance challenges can be identified at an early stage, and products can be modified or redesigned if required in a much shorter period. RPT also facilitates small scale manufacturing, allowing tasks like test marketing, customer validation, and regulatory compliance. Entrepreneurs can learn what may potentially work in the market place and change plans accordingly.

Benefits

– Advances “time to market” turn-around.

– Saves on tooling cost with on demand 3D printing.

– Reduces waste with additive manufacturing.

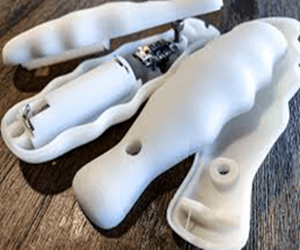

– Improve lives, one customized part at one time for medical application.

– Saves weight with complex part designs.

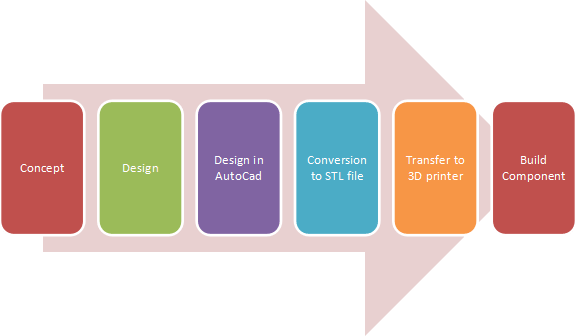

Design Assistance for 3 D printing

Share your concept, a sketch, a 2D drawing, we will work with you to create 3D CAD to serve your need and similarly a 3D CAD drawings could be generated from an object.

Mentoring for product development

Our team of industry experts in various domains can work with you from concept to commercialisation.

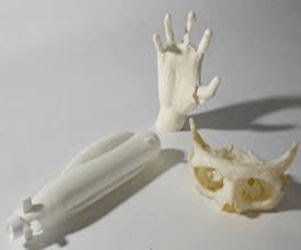

A product needs more than one kind of material and process to deliver intended performance. We offer the following facilities and services: Additive Manufacturing – 3D printing of objects in a wide range of materials, directly from CAD data.

Additive manufacturing, also known as 3D printing, is the exact opposite of the traditional way of making objects. Instead of machining or “subtracting” material to form an object – much like how a sculptor cuts away clay – 3D printing adds layer upon layer of material to build an object. Product designers and engineers upload a digital (CAD) file to a 3D printer, which then prints a solid 3D object. Our facility is equipped with industry manufacturing grade 3D printer that has component-built size of 406x355x406 mm. It is enabled to build components with our familiar materials.

Facility

– Production Grade all material enabled 3D printers

– Prototype 3D printer

– Dental Machine

Our facility is equipped with industry manufacturing grade 3D printer that has component-built size of 406x355x406 mm. It is enabled to build components with our familiar materials. Considering advanced complexity and demanding requirements of current manufacturers, it is fully loaded with material range that can be used for various applications such as Ultem 1010 for biomedical devices, ABS-ESD7 for antistatic Electronics, Ultem 9085 for Aerospace, plastic molding, Nylon12 CF & Nylon 6 for jigs, fixtures and ABS, ASA for prototyping. It will fulfil most of the industrial application needs. You may refer to the table below for characteristics of materials. Any application / component demanding specific characteristics can be built in our facility.

Dental Machine

With a tray size of 300 x 200 x 100 mm (11.81 x 7.87 x 3.94 in.) and three print modes, we can Print precise 3D dental models in High-quality print mode for applications like diagnostic wax-ups and removable partial-denture casting patterns. The machine offers maximum versatility of selecting material of need.

Model Materials:

Clear Bio-compatible (MED610)

VeroDentPlus™ (MED690)

VeroGlaze™ (MED620)

Materials Available for 3D Printing and Their Characteristics

| Sr. No | Material | Characteristics |

|---|---|---|

| 1 | ABS-M30 / ABSplus | Versatile material |

| 2 | ABS-ESD7 | Electrostatic Dissipative |

| 3 | ULTEM 1010 | Bio Compatible, Chemical resistance & High Temperature material (Only on 900mc) |

| 4 | Polycarbonate | High Tensile Strength |

| 5 | PC-ABS | High Impact Strength |

| 6 | ABS-M30i | Biocompatible (ISO-10993) |

| 7 | PC-ISO | Biocompatible (ISO-10993) |

| 8 | Nylon 12 | High Fatigue Resistance |

| 9 | ULTEM 9085 | High Strength and good chemical resistance, FST Certified hence can be used for aerospace application |

| 10 | ST-130 | Sacrificial Tooling |

| 11 | ANTERO | High Strength- High chemical resistance, Wear Resistant |

| 12 | Nylon 12CF | High Strength- , Jigs Fixtures, Tooling |

| 13 | Nylon 6 | Fixtures |

We have experienced team that can support/mentor you for development of Electronics circuits and automation system. The infrastructure is self-sufficient to develop prototype and take trials.

Electronics Prototyping Equipment include

– PCB Making Machine

– SMD Mounting and Soldering

– Basic Testing Equipment

– Component bank with range of

o Controllers

o Motors

o WI Fi modules

o Motor Controllers

o Passive Components

The innovation lab is fully equipped with necessary infrastructure to independently work on your project. Our experts from Project Clinic Can guide you to resolve technical issues.

Laser Cutting Machine

- Mixed Metal and Plastics

Sheet Metal Working

- Punching

- Blanking

Testing Services

MIT has an NABL accredited laboratory facility which includes ICP-OES, AAS, UV-Spectrophotometer, GCMS, HPLC etc. MIT – SHIMADZU – MIT – Shimadzu Analytical Testing Laboratory is established at Department of Plastics & Polymer Engineering in Collaboration with Shimadzu(Asia-Pacific), Singapore. The Laboratory is equipped with modern testing instruments like FTIR, UV-VIS, DSC & TGA.

ISO-9001:2015 and OHSAS 18001:2007 certified facility, offers testing services for sectors like agriculture, environment, food, pesticides, fertilizer, polymer, pharma, biotechnology etc.

This added advantage of access to high end testing facility reduces time, cost and hassles for the entrepreneurs.

Small Scale Manufacturing

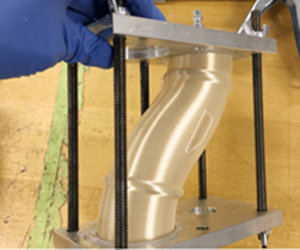

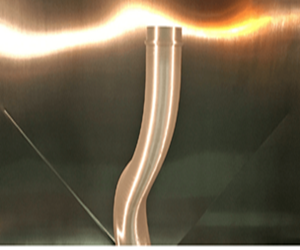

Once prototype is ready, tested and a small batch needs to be produced for testing, customer feedback and compliance needs. We offer this facility to the prospective entrepreneurs.

We can produce low volume, customized parts on demand, without the high cost and long lead times of traditional manufacturing. A diverse material selection and simple post processing enables you to quickly meet varied production demands. The proven accuracy and uptime reliability of 3 D printers provides consistent results.

Our facility is also useful for making cost effective and faster :

1. Jigs and Fixtures

2. Dies and molds for small batch

3. End of Arm Effectors

4. Ducts

5. Complex shapes production items as one unit.

6. Sacrificial, Autoclave capable, strong and light weight tooling

Training Services

You may get your staff trained in various disciplines in which MIT offers skill development training.

– Additive Manufacturing

– CAD/CAM/CAE services

– CNC Operations

– Automation and Mechatronics

– Mould designing and testing

– Trial runs of Plastic Injection Mould products

– Polymeric and other Material testing